Degreasers

The use of degreasers is the first and most important step in the surface cleaning process. There are oils on the metal that we use to stop the reaction with air. The function of these oils is to prevent contact with oxygen in the air and prevent the metal from rusting. These same oils make it impossible to perform phosphating and chromating. Therefore, the metal surface must be free of oil, dirt and rust.

Degreasers tips

In the metal and painting industry, oil protects the sheets from corrosion. Almost every type of metal contains a small or large amount of oil. Although oils are generally in the form of mineral oil, we also use animal fats.There should be no oil on the parts that have a coating or paint. If we do not completely remove the oil from the metal surface, we cannot successfully apply surface treatment applications. Yellowing, color differences and adhesion problems can be caused by the oiliness of the metal. Degreasers break the bonds between the fat molecules and remove them from the surface. Therefore, after we have completely removed the oil from the metal with the help of degreasers, we must apply the chromate or phosphate coating.

Types of degreasers

We divide the degreasing process into different categories from a chemical and practical perspective. From a chemical perspective, we can divide the materials into three categories: acidic, alkaline, and neutral. From a practical perspective, we can also divide them into methods such as spraying, immersion, ultrasonic, and hand wiping.

Important parameters to consider in degreasing baths are: temperature, time, total alkalinity, total acid, concentration and pressure. In the rinsing bath it is easy to understand whether any oil remains on a part of the metal. The water-break test is applied. If water particles remain on the rinsed part, it means that we did not completely degrease the metal.

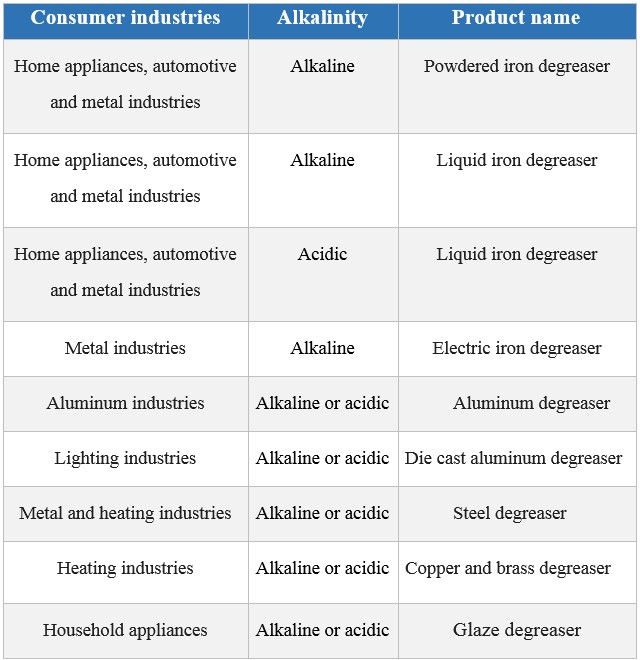

Depending on the characteristics of the metal and the operating conditions, we can say which method and which chemical to use. Degreasers are suitable for use before iron phosphating, zinc phosphate coating, manganese phosphate coating and chromate coating. Azarasa Company produces a wide range of degreasers based on the above-mentioned characteristics. We have listed some of the degreasers in the table below.

Share: