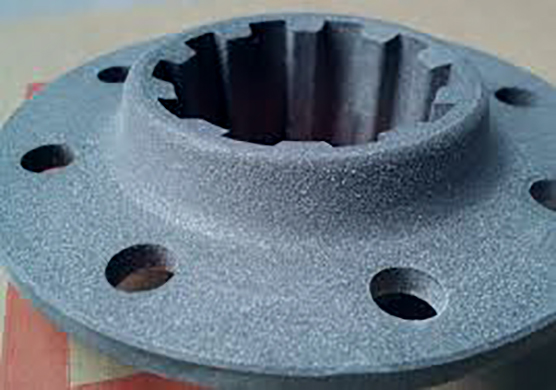

Zinc phosphate coating

Zinc phosphate coatings, which are often gray in color, are chemically stable. It can prevent metal surfaces from aging. They act as a corrosion-resistant coating that you can apply to the metal surface as an undercoat.

The zinc phosphating process can be used in either dip or spray lines. This phosphating creates a crystalline coating on the metal. Depending on the product used, the weight of the zinc phosphate coating can vary from 2 to 35 g/m2. A coating with high crystal and thickness is not suitable for pre-painting.

Alkaline or acidic degreasing should precede the phosphate coating. Phosphating zinc is not suitable for oily and rusty metal. In order for the zinc phosphate crystals to be thin and homogeneous, activation should be applied just before the phosphate bath. Important parameters to consider are; total acid, free acid, temperature, time, iron point and accelerator point.

What are the characteristics of zinc phosphate?

1- Durability and corrosion resistance

As a non-conductor, it restricts the flow of current and offers high resistance to galvanic corrosion. As a result, this coating on the metal surface can be used for a long time. Zinc phosphate coating is generally used for metal parts that require long-term resistance to corrosion and impact.

2- Resistance to harsh weather conditions

Since zinc phosphate has a colorless coating, it can reflect ultraviolet rays. This distinctive feature allows the coating to remain excellent even in harsh environmental conditions. Zinc phosphate coating is generally used for parts that are used outdoors.

3- Adhesion and base coating

These coatings are porous, so paints and coatings can adhere to each other to a great extent, extending their life and eliminating the need for reapplication. It offers the best paint adhesion compared to other coatings, which is why it plays a significant role in many industries. Zinc phosphating is used in the automotive industry, in the wiring and plumbing industry. It is a suitable coating method for iron, steel and galvanized parts.

Share: