Alkaline degreaser

It mainly consists of alkalis, surfactants and emulsifiers that, by suspending oil particles in the aqueous phase, make it easier to wash the oil from the metal surface. Alkaline degreaser can be used at different temperatures and by immersion, spraying and electrical methods, depending on the metal type and the type of operation. We mainly use them as hot solutions. Usually, a temperature between 60-95 degrees Celsius, a processing time of 5-10 minutes and a concentration of 3-10% are sufficient for degreasing.

Properties of alkaline degreaser

1- High cleaning power: Due to their alkaline nature, these compounds have high cleaning power and are capable of removing very tough and sticky contaminants.

2- Alkalinity: The pH of these solutions is higher than 7, which increases their cleaning power.

3- Emulsification: These compounds have the ability to emulsify fats, meaning they convert them into fine particles and prevent the fat from re-adhering to the surface.

4- Additives: Depending on the application, they contain additives such as surfactants (surface-active substances), anti-corrosion agents, corrosion inhibitors, etc.

5- Relatively affordable price: They are cost-effective compared to other methods.

6- Availability: They are easily available.

Applications

We use alkaline degreasers in various industries, including:

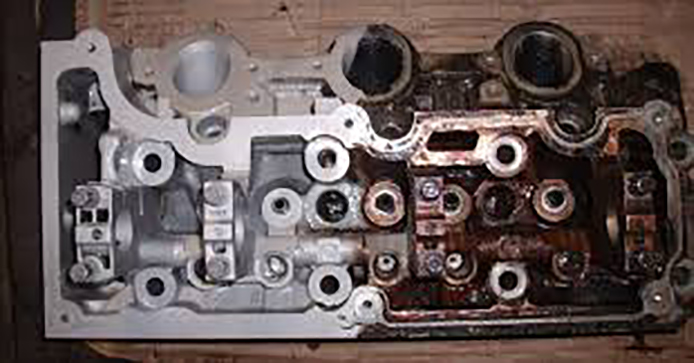

-Automotive industry: Cleaning car parts before painting or coating

-Metal industry: Cleaning metal parts before subsequent operations such as welding, assembly or plating

-Printing industry: For cleaning printing plates and related equipment

-Cleaning electronic components: In this case, we use an alkaline degreaser that is compatible with electronic components.

Share: